What is five-axis CNC machining?

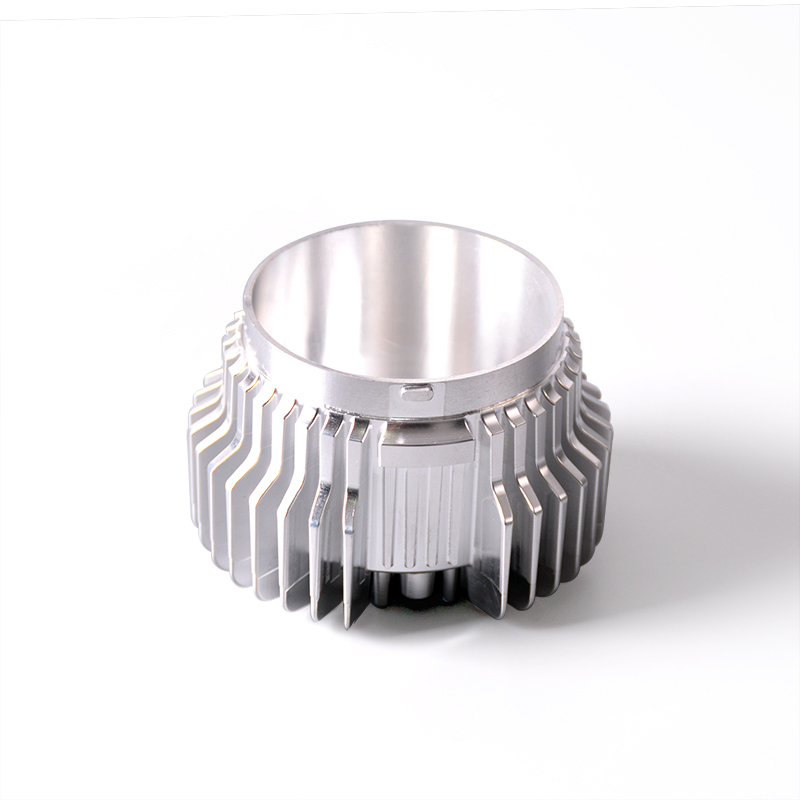

It uses reduced material processing technology to provide unlimited possibilities for part creation. The workpiece is cut to the desired shape and size using a cutting tool that works on five axes.

5-axis machining provides increased accuracy and precision, efficiency and reliability. The increase in the number of axes also gives the five-axis milling machine the ability to be better than similar products. In addition, the process allows for full automation and management using computer digital control (CNC).

This process involves the cutting tool moving on five axes simultaneously. 5-axis CNC machines provide three linear axes and two rotating axes working simultaneously to realize complex parts. This often increases the tilt of the table or tool, which increases rotation and movement.

The difference between five axes and three axes

Three-axis machine tool processing, in the processing of 3D workpiece accuracy is not high, such as impeller, although it can be processed, but the accuracy is low, and the tool is not perpendicular to the processing surface processing, the tool is not the largest output; There are also some workpieces that cannot be processed with a three-week machine.

Five-axis machine tool processing, five-axis linkage is not the focus, the focus is RTCP or TCP, that is, the tool center point control, through adjustment, you can ensure that the machining, the tool is perpendicular to the machining surface, to ensure that the tool is in the maximum output state, but also to ensure the accuracy of processing.

Why choose our 5-axis machining services?

1. Reduce the number of clamping. Due to the existence of two rotating axes of the five-axis machine tool, the tool can approach the workpiece from any direction, and all surfaces except the mounting surface can be machined at one time. "Reducing the number of clamping" can be said to kill two birds with one stone for the pursuit of efficient and high-precision machining. On the one hand, reducing the number of clamping can save time, reduce the labor intensity of workers, and improve the processing efficiency; On the other hand, the errors that may be brought by the assembly and clamping errors can be reduced as much as possible to ensure the machining accuracy.

2. Maintain the best cutting state of the tool and improve cutting conditions. Due to the use of five-axis machine tools, the tool can be approached from any direction to the workpiece, so that the tool can be used at the most appropriate Angle to cut the workpiece. It can also improve the processing efficiency and processing quality.

3. Effectively avoid interference. Also because of the existence of two rotating axes of the five-axis machine tool, the tool can approach the workpiece from any direction, making the machining path flexible. It can effectively avoid interference problems during processing.

4. Shorten the development cycle. This is also the natural effect of improving quality and efficiency.