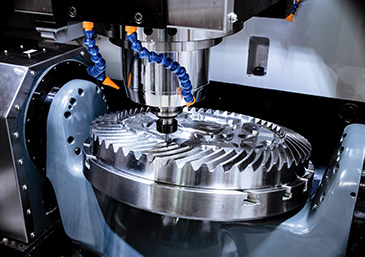

10 CNC experience summaries, what is CNC machining?

CNC machining, also known as CNC machining, refers to the use of computer-controlled tools for precision machining. This method has become popular in various industries due to its many advantages such as stable processing quality, high precision, and the ability to process complex shapes. However, human factors and experience must be taken into account during actual machining as they can have a significant impact on the final quality.

To solve this problem, a CNC machinist with ten years of experience shared twelve valuable lessons for efficient CNC machining. These lessons learned can help improve the overall process and achieve better results.

The first lesson focuses on the division of CNC machining processes. There are different ways to effectively compartmentalize these processes. One such approach is the toolset sequencing approach, which divides processes according to the tools used. By using the same tool for complete parts, unnecessary tool changes are avoided, reducing idle time and positioning errors.

Another method discussed is the machining part sequencing method. This method divides the machined parts into different parts according to their structural characteristics such as internal shape, external shape, curved surface or plane. It is recommended to process the flat surface and positioning surface first, and then process the hole. Similarly, simple geometric shapes should be processed first, and then complex geometric shapes should be processed. Parts with lower accuracy requirements should be processed first, and then parts with higher accuracy requirements should be processed.

The third lesson introduces the coarse and fine classification methods of CNC machining. This method is particularly useful for parts that are prone to deformation during rough machining. In order to correct any deformation, it is necessary to divide the machining into roughing and finishing stages. This ensures that the processing quality is improved and the required standards are met.

Other lessons shared by experienced CNC machinists include choosing appropriate cutting speeds and feeds, using the right tool for a specific material, optimizing tool paths to reduce tool wear and increase efficiency, implementing proper fixture design, and maintaining a clean job environment, understanding and utilizing different tool paths. Types of cutting fluids, regular tool maintenance, adjusting cutting parameters according to material properties, calibrating the accuracy of measuring tools, and constantly learning and updating CNC machining technical knowledge.

Collectively, these twelve valuable lessons provide guidance for achieving efficient, high-quality CNC machining. By implementing these strategies, both experienced and novice CNC machinists can improve their skills, optimize processes, and deliver superior results.