Can CNC machines cut aluminum?

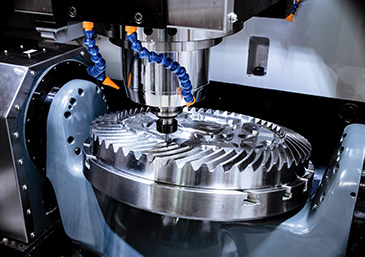

CNC machine tools have revolutionized manufacturing with their precision and ability to produce complex parts. One of the commonly used materials used in CNC machining processes is aluminum. Aluminum is lightweight, durable and has excellent processability, making it ideal for a variety of applications. In this article, we'll explore the capabilities of CNC machines for cutting aluminum and the benefits of custom CNC milling.

To answer the question at hand, yes, CNC machines can definitely cut aluminum. In fact, CNC machine tools are widely used for aluminum machining due to their high cutting speed, accuracy and repeatability. Whether it's a simple flat shape or a complex 3D design, CNC machines can handle aluminum cutting with ease.

CNC mills are often the first choice when it comes to cutting aluminum. CNC milling is a versatile process that involves using rotating cutting tools to remove material to create precise shapes and features. By utilizing custom CNC milling technology, manufacturers can achieve complex designs and dimensions that are typically not possible with manual machining methods.

The key to cutting aluminum with a CNC machine lies in the tooling and machining parameters. Carbide end mills are designed specifically for aluminum cutting and are widely used due to their sharp edges, high hardness, and heat resistance. Cutting speeds, feed rates and depth of cut are all carefully set to ensure efficient material removal without compromising the quality of the final product.

Another advantage of using a CNC machine to cut aluminum is the ability to automate the process. Once the machine is programmed to the desired design, it can replicate the same cut repeatedly with high accuracy. This not only improves productivity but also ensures consistency and accuracy, which are critical in industries such as aerospace and automotive manufacturing.

Custom CNC milling further enhances the CNC machine's ability to cut aluminum. With custom CNC milling, manufacturers can customize the machining process to meet specific requirements and achieve unique designs. This includes the use of specialized tools, advanced software and programming techniques to optimize the aluminum machining process.

The benefits of using custom CNC milling to cut aluminum are many. First and foremost, it can produce complex shapes and features that may not be achievable using traditional machining methods. Custom CNC milling also produces high-quality aluminum parts by reducing production time, reducing material waste, and improving surface finish.

In addition to cutting aluminum, CNC machines are also capable of other machining operations such as drilling, tapping and threading. This versatility makes them invaluable in various industries including aerospace, automotive, electronics and medical.

All in all, CNC machines do cut aluminum efficiently. With their precision, speed and ability to replicate cuts, CNC machines have become the first choice for aluminum machining. Custom CNC milling further enhances their capabilities, allowing manufacturers to achieve complex designs and dimensions. Whether it's a low-volume production or a large-scale project, CNC machines provide the efficiency and precision you need to cut aluminum.