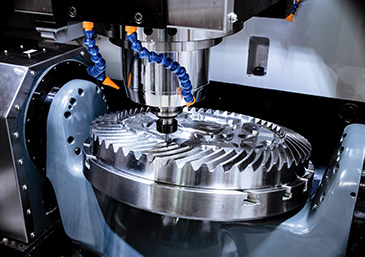

Exploring the Applications and Advantages of CNC Machining Technology

In modern manufacturing, Computer Numerical Control (CNC) machining technology is highly regarded for its precision, efficiency, and reliability. This article explores the application areas and advantages of CNC machining technology to help readers understand why it is considered a crucial technology in manufacturing.

What is CNC Machining?

CNC machining is a method of operating and controlling machine tools through pre-programmed computer software. With its automation and precision control systems, CNC can produce parts with complex shapes. This technology is widely used in automotive manufacturing, aerospace, medical equipment, and many other fields.

Applications of CNC Machining

1. Automotive Manufacturing

CNC technology is extensively used in automotive manufacturing for producing complex automotive parts, such as engine components, transmission systems, and body structures.

2. Aerospace

In the aerospace sector, CNC machining can produce high-precision and complex aerospace components that meet the stringent structural and performance requirements of aircraft.

3. Medical Equipment

CNC technology plays a vital role in the manufacturing of medical equipment, capable of producing precise medical instruments and devices such as artificial joints, implants, and surgical tools.

4. General Manufacturing

Additionally, CNC technology is widely used in general manufacturing for processing metals, plastics, composites, and other materials to produce various parts and products.

Advantages of CNC Machining

1. High Precision

CNC machining achieves high precision, ensuring the accuracy and consistency of machined parts.

2. High Efficiency

CNC machining enables automated production, enhancing production efficiency and speed, while saving labor and time costs.

3. Flexible Machining Capabilities

CNC technology offers flexible machining capabilities, allowing quick adjustments and changes to meet various production needs.

4. Strong Repeatability

CNC machining ensures consistent quality and precision of products, guaranteeing repeatability.

Conclusion

CNC machining technology plays an irreplaceable role in modern manufacturing. Its high precision, efficiency, and flexibility make it the first choice for many manufacturers. Although some may view CNC machining as costly, understanding its applications and advantages can provide better insight into leveraging this technology. For manufacturing professionals, mastering the applications of CNC machining technology is key to improving production efficiency and product quality.