Benefits of 3D Printing

Rapid Prototyping:

1.Quick Turnaround: 3D printing significantly reduces the time required to go from design to physical prototype, enabling faster iteration and development cycles.

2.Design Validation: Allows for quick testing and validation of designs, helping identify and rectify issues early in the development process.

Customization:

1.Personalized Products: 3D printing enables the creation of customized products tailored to individual needs and preferences, such as custom-fit medical implants or bespoke consumer goods.

2.Small Batch Production: Ideal for producing small quantities of customized products economically, which is often not feasible with traditional manufacturing.

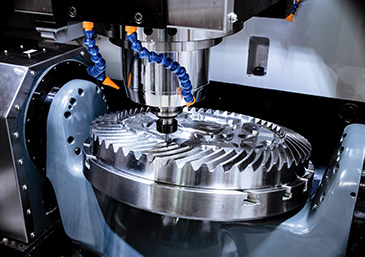

Complex Geometries:

1.Design Freedom: 3D printing allows the creation of complex and intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

2.Lightweight Structures: Enables the production of lightweight structures with optimized strength-to-weight ratios, useful in industries like aerospace and automotive.

Material Efficiency:

1.Minimal Waste: Unlike subtractive manufacturing, which removes material from a larger block, 3D printing only uses the material necessary to create the part, reducing waste.

2.Recyclable Materials: Many 3D printing materials are recyclable, further enhancing the environmental benefits.

Cost-Effective Production:

1.Tooling and Molds: Eliminates the need for expensive tooling and molds, reducing the cost and time associated with setting up traditional manufacturing processes.

2.Economical for Small Runs: Cost-effective for low-volume production runs, making it ideal for startups and small businesses.

On-Demand Manufacturing:

1.Inventory Reduction: Products can be printed on demand, reducing the need for large inventories and the associated storage costs.

2.Supply Chain Flexibility: Enhances supply chain resilience by allowing localized production and reducing dependence on distant suppliers.

Innovation and Experimentation:

1.Creative Freedom: Encourages innovation by providing designers and engineers with the flexibility to experiment with new ideas and complex designs without the constraints of traditional manufacturing.

2.Prototyping and Testing: Facilitates rapid prototyping and testing of new concepts, accelerating the pace of innovation.

Sustainability:

1.Energy Efficiency: Some 3D printing processes consume less energy compared to traditional manufacturing methods.

2.Reduced Transportation: Localized production reduces the carbon footprint associated with transporting goods from distant manufacturing sites.

Reduced Lead Times:

1.Faster Production: Shortens the lead times for producing parts and products, enabling companies to respond more quickly to market demands.

Educational and Research Applications:

1.Hands-On Learning: Provides students and researchers with hands-on experience in design, engineering, and manufacturing, fostering a deeper understanding of these fields.

2.Research and Development: Supports R&D activities by allowing for the rapid creation and testing of experimental designs and prototypes.

Overall, 3D printing offers numerous advantages that make it a valuable tool in modern manufacturing, product development, and innovation across various industries.