Introduction to CNC

Introduction to CNC

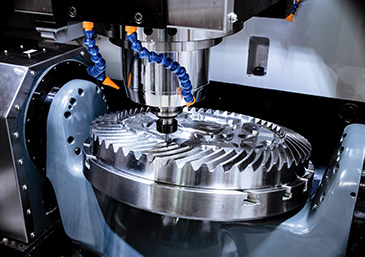

CNC (Computer Numerical Control) is an automated control technology used for precision machining by controlling machine tools and equipment. By using computers to control the movement and operation of CNC machines, CNC achieves high precision and high efficiency in machining. Here is an introduction to the basics of CNC:

Basic Concepts of CNC

1.Definition: CNC technology uses computer programs to automatically control the operation of machine tools, achieving precise machining of workpieces. Machine tools can include milling machines, lathes, grinders, drills, etc.

2.Working Principle: CNC systems control the movement of machine tools through pre-written programs (usually G-codes and M-codes). The programs include parameters such as the machining path of the workpiece, cutting speed, and feed rate.

3.Components:

1.Controller: The computer or CNC system responsible for executing the machining program and controlling the machine tool's operation.

2.Drive System: Converts the instructions from the controller into mechanical motion, including motors and drive mechanisms.

3.Machine Tool: The equipment that performs the actual machining operations, such as milling machines, lathes, etc.

4.Feedback System: Detects the actual movement of the machine tool and provides feedback to the controller for adjustments.

Major Advantages of CNC

1.High Precision: CNC machines can achieve very high machining precision, with errors typically in the micron range.

2.High Efficiency: Automated machining reduces manual intervention, improving production efficiency and machining speed.

3.Complex Machining: Capable of machining complex-shaped workpieces, especially suitable for complex surfaces and multi-axis linkage machining.

4.Consistency: Capable of producing highly consistent products in batches, reducing errors caused by human factors.

5.Flexibility: By modifying the program, machining processes can be quickly adjusted to meet different production needs.

Types of CNC Machines

1.CNC Milling Machine: Used for milling operations, capable of machining surfaces, grooves, contours, complex surfaces, etc., on workpieces.

2.CNC Lathe: Used for turning operations, suitable for machining rotational parts such as shafts and discs.

3.CNC Router: Used for engraving and cutting materials, widely used in woodworking, advertising, and crafts.

4.CNC Grinding Machine: Used for grinding operations, suitable for high-precision surfaces and complex shapes.

5.CNC Machining Center: Integrates multiple functions such as milling, drilling, and tapping, suitable for multi-process centralized machining of complex parts.

CNC Programming

1.G-Codes and M-Codes:

1.G-Codes (Geometric Codes): Control the geometric actions of the machine tool, such as moving, interpolating, and positioning.

2.M-Codes (Miscellaneous Codes): Control auxiliary functions of the machine tool, such as tool changes, coolant switches, and program ends.

2.CAM Software (Computer-Aided Manufacturing): Software used to generate CNC machining programs. By importing CAD models, it can automatically generate G-codes.

3.Manual Programming: Operators directly write G-codes and M-codes, suitable for simple machining tasks.

4.Automatic Programming: Uses CAM software to generate machining programs, suitable for complex tasks and mass production.

Applications of CNC

1.Manufacturing: Widely used in the automotive, aerospace, mechanical, and electronics industries for precision machining of parts.

2.Mold Making: Used for manufacturing various molds, including injection molds, stamping molds, and die-casting molds.

3.Medical Devices: Used for machining high-precision medical equipment and tools.

4.Electronics Industry: Used for machining components of electronic products such as phones and computers.

5.Furniture Making: Used in woodworking and furniture manufacturing, including engraving and cutting complex patterns.

Conclusion

CNC technology is a crucial part of modern manufacturing, characterized by high precision, high efficiency, and high flexibility. As technology continues to advance, CNC machines are being applied more widely across various fields, significantly enhancing production efficiency and product quality. If you have more specific questions or need further information, please let me know.