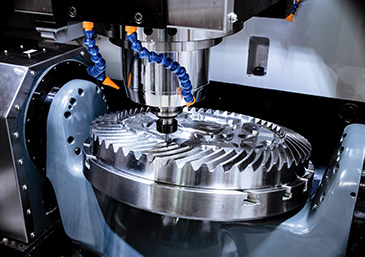

Five Common Types of CNC Machine Tools

In today's advanced manufacturing industry, CNC machining has become an integral part of the production process. CNC, short for Computer Numerical Control, refers to automation where a

revolutionized the way we manufacture products, enabling greater precision and efficiency in various industries including automotive, aerospace and electronics. In this article, we’ll explore five common types of CNC machine tools that are widely used in manufacturing today.

1. CNC Milling Machine: CNC milling machines are probably the most widely used CNC machine tools in the industry. They utilize rotating cutting tools to remove material from the workpiece by gradually moving the workpiece toward the cutting tool. These machines can perform a variety of operations on a variety of materials, including metal, plastic, and wood, including drilling, cutting, and shaping. CNC milling machines are known for their versatility and ability to handle complex geometries with high precision.

2. CNC Lathe: A CNC lathe, also known as a CNC lathe, is used to produce cylindrical parts by rotating the workpiece against a cutting tool. This type of machine is typically used to make symmetrical or round parts such as shafts, bushings, and threaded fasteners. CNC lathes can perform operations such as turning, facing, threading and grooving. They are favored for their ability to produce high-precision parts with excellent surface finishes.

3. CNC plasma cutting machine: CNC plasma cutting machine is specially designed for cutting metal materials using a plasma torch. This versatile machine is often used to machine complex shapes, curves or perforations in sheet metal. Plasma cutting relies on a conductive gas, such as compressed air, to create a plasma arc between the cutting torch and the workpiece. CNC plasma cutting machines are widely used in industries such as automotive, HVAC, and construction that require precise metal cutting.

4. CNC milling machine: CNC milling machine is mainly used for cutting and shaping wood, plastic, foam and other soft materials. These machines use a rotating tool, usually a milling cutter, to gradually remove material from a workpiece. CNC milling machines are often used in the woodworking industry to create furniture, cabinets, and decorative items. They are favored for their ability to produce complex designs and patterns with high precision.

5. CNC laser cutting machine: CNC laser cutting machine uses high-power laser beam to cut various materials, including metal, plastic and fabric. The laser beam is guided by computer-controlled mirrors, precisely following the programmed path and producing precise cuts. Laser cutting delivers fast, precise results, making it ideal for industries such as signage, automotive and aerospace.

In summary, CNC machining has revolutionized manufacturing by providing high precision, efficiency, and versatility. The five common CNC machine tools mentioned above, namely CNC milling machines, CNC lathes, CNC plasma cutting machines, CNC routers and CNC laser cutting machines, meet different manufacturing needs and materials. As technology continues to advance, CNC machine tools are likely to become more complex and powerful, further increasing manufacturing capabilities and productivity.